Search the Community

Showing results for tags 'powertrain'.

-

Another piece of the next-generation Jeep Wrangler has been unearthed. The Truth About Cars has uncovered a document submitted to the National Highway Traffic Safety Administration (NHTSA) which reveals some partial details on the JL Wrangler's powertrains. The documents revealed that the Wrangler would come with a 3.6L V6 with 285 horsepower and a turbocharged 2.0L four-cylinder offering up 368 horsepower. No, this isn't a misprint. The other bit of information that can be gleaned from this document is that the Wrangler will only be initially offered as a four-door model - something we first we reported back in August. Before anyone begins to panic because the two-door and diesel engine are not listed, we know both are happening thanks to spy shots and other leaks. Source: The Truth About Cars

- 21 comments

-

- jeep

- powertrain

-

(and 3 more)

Tagged with:

-

Another piece of the next-generation Jeep Wrangler has been unearthed. The Truth About Cars has uncovered a document submitted to the National Highway Traffic Safety Administration (NHTSA) which reveals some partial details on the JL Wrangler's powertrains. The documents revealed that the Wrangler would come with a 3.6L V6 with 285 horsepower and a turbocharged 2.0L four-cylinder offering up 368 horsepower. No, this isn't a misprint. The other bit of information that can be gleaned from this document is that the Wrangler will only be initially offered as a four-door model - something we first we reported back in August. Before anyone begins to panic because the two-door and diesel engine are not listed, we know both are happening thanks to spy shots and other leaks. Source: The Truth About Cars View full article

- 21 replies

-

- jeep

- powertrain

-

(and 3 more)

Tagged with:

-

Pecking Order of the Jeep 4x4 systems? Thanks to Drew, I had overlooked the web page that Jeep has on their powertrain systems. http://www.jeep.com/en/4x4/ Now that we have this great resource, I need some help in figuring out the pecking order of where things line up or are similar. Why you ask? Easy in the sense that my son who bought out of college his first new auto, a 2012 Jeep Patriot Latitude Trail rated edition is now ready to step up to a nicer auto and has decided to get a Jeep Grand Cherokee. We have tested them and he pretty much has all the details hammered out except for one question he asked me. I have searched and searched various jeep forums and no one really has a good feeling for where the various 4x4 systems line up in comparison to other products. So the question is as follows: Where does the Patriot Latitude Trail Rated system line up in comparison to the Jeep Grand Cherokee 4x4 system options? Is it between the the Quadra Drive II and Quadra Trac 1 system or below the Quadra Trac 1 system? My son wants equal to what he already has and is not sure if he goes with the all black Jeep GC Altitude edition if he is moving up or down in the 4x4 department? If the system is above the Altitude Quadra Trac 1 system, then he will have to go with a higher trim level. He is trying to get as much as possible by staying in his chosen price range. So anyone know how the Jeep 4x4 systems line up against each other, especially the trail rated program?

- 2 replies

-

- 4x4

- comparison

-

(and 3 more)

Tagged with:

-

It is no secret that Bentley is working on a plug-in hybrid variant of the Bentayga SUV due out next year. But Bentley CEO Wolfgang Duerheimer revealed that all of their models would have the option of a plug-in hybrid in the coming years. Speaking at the Automotive News World Conference, Duerheimer said this powertrain provides the best of two worlds - allowing owners to drive their vehicles on electric power only in cities where gas engines might be restricted and traveling for long distances without having to recharge the battery. “To cover long distances and to make it from one city to another -- and you travel long distances in the U.S. -- I think the combustion engine will follow us for a long time,” Duerheimer said. Following the Bentayga, the next-generation Continental GT will be the next model to get a plug-in hybrid option. Source: Automotive News (Subscription Required)

- 9 comments

-

It is no secret that Bentley is working on a plug-in hybrid variant of the Bentayga SUV due out next year. But Bentley CEO Wolfgang Duerheimer revealed that all of their models would have the option of a plug-in hybrid in the coming years. Speaking at the Automotive News World Conference, Duerheimer said this powertrain provides the best of two worlds - allowing owners to drive their vehicles on electric power only in cities where gas engines might be restricted and traveling for long distances without having to recharge the battery. “To cover long distances and to make it from one city to another -- and you travel long distances in the U.S. -- I think the combustion engine will follow us for a long time,” Duerheimer said. Following the Bentayga, the next-generation Continental GT will be the next model to get a plug-in hybrid option. Source: Automotive News (Subscription Required) View full article

-

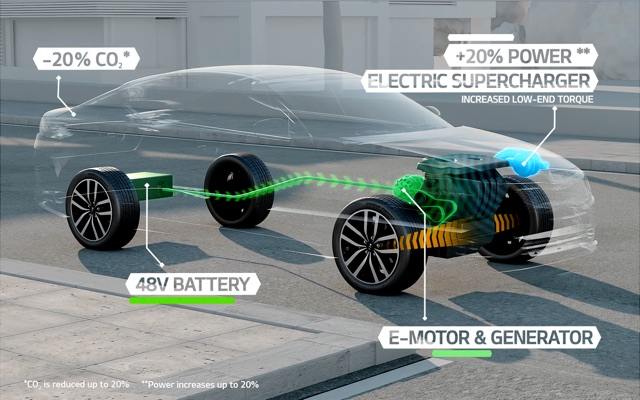

Kia had an interesting powertrain concept on the floor of the 2014 Paris Motor Show. Revealed in the Optima T-Hybrid, the powertrain paired a 1.7L turbodiesel four-cylinder with a 48v electric supercharger. This worked in conjunction with a 48V starter/generator that turned it into a mild hybrid. Kia said this powertrain would cut emissions and fuel consumption for any vehicle by 15 to 20 percent. Since showing this powertrain, Kia has been hard at work on this project But then the Volkswagen diesel emission scandal hit and it has caused many automakers, Kia included, to rethink projects involving diesel engines. Speaking with Autocar, Hyundai-Kia's performance development boss Albert Biermann said it's becoming harder to justifying the costs to develop next-generation diesel engines in light of the Volkswagen mess and stricter emission standards. “The research project is still going on, but the cost of electric motors and batteries in a hybrid is already significant. The question is whether it is really necessary to throw in a more expensive diesel engine.” If Kia decides to scrap the diesel part of this powertrain, their efforts will not go to waste. Biermann said this system could be re-engineered for a gas engine. Source: Autocar View full article

- 2 replies

-

- diesel hybrid

- hybrid

-

(and 3 more)

Tagged with:

-

Kia had an interesting powertrain concept on the floor of the 2014 Paris Motor Show. Revealed in the Optima T-Hybrid, the powertrain paired a 1.7L turbodiesel four-cylinder with a 48v electric supercharger. This worked in conjunction with a 48V starter/generator that turned it into a mild hybrid. Kia said this powertrain would cut emissions and fuel consumption for any vehicle by 15 to 20 percent. Since showing this powertrain, Kia has been hard at work on this project But then the Volkswagen diesel emission scandal hit and it has caused many automakers, Kia included, to rethink projects involving diesel engines. Speaking with Autocar, Hyundai-Kia's performance development boss Albert Biermann said it's becoming harder to justifying the costs to develop next-generation diesel engines in light of the Volkswagen mess and stricter emission standards. “The research project is still going on, but the cost of electric motors and batteries in a hybrid is already significant. The question is whether it is really necessary to throw in a more expensive diesel engine.” If Kia decides to scrap the diesel part of this powertrain, their efforts will not go to waste. Biermann said this system could be re-engineered for a gas engine. Source: Autocar

- 2 comments

-

- diesel hybrid

- hybrid

-

(and 3 more)

Tagged with:

-

Imagine a future where the powertrain from the Chevrolet Volt is found under the hood of another automaker's vehicle. This might actually become reality if General Motors global powertrain chief Dan Nicholson gets his wish answered. Speaking to Automotive News, Nicholson said he was open to sharing the Volt's powertrain. "We want to be the partner of choice in propulsion system development in this complex and turbulent era we are approaching," said Nicholson. If this idea is given the green light, it would pay dividends for GM and the other automaker. For GM, giving the Volt powertrain to another automaker would drive costs down due to larger economies of scale. The other automaker wouldn't have to spend so much on research and development for a powertrain like the Volt. Whether this happens or not is a wait and see matter. Source: Automotive News (Subscription Required) View full article

- 6 replies

-

- Chevrolet

- Chevrolet Volt

-

(and 4 more)

Tagged with:

-

Imagine a future where the powertrain from the Chevrolet Volt is found under the hood of another automaker's vehicle. This might actually become reality if General Motors global powertrain chief Dan Nicholson gets his wish answered. Speaking to Automotive News, Nicholson said he was open to sharing the Volt's powertrain. "We want to be the partner of choice in propulsion system development in this complex and turbulent era we are approaching," said Nicholson. If this idea is given the green light, it would pay dividends for GM and the other automaker. For GM, giving the Volt powertrain to another automaker would drive costs down due to larger economies of scale. The other automaker wouldn't have to spend so much on research and development for a powertrain like the Volt. Whether this happens or not is a wait and see matter. Source: Automotive News (Subscription Required)

- 6 comments

-

- Chevrolet

- Chevrolet Volt

-

(and 4 more)

Tagged with:

-

The long wait for the Acura NSX continues. Automobile reports that Acura has pushed back production from this fall to next Spring due to a change in engine layout. The original plan was to use a naturally-aspirated V6 for the vehicle, but it was decided to add turbochargers to the engine. This has caused Acura to build a bespoke twin-turbo V6 and change the engine layout to a longitudinal configuration. This delay puts the transformation from the NSX being a concept car to production car at about four years. One item that is still up in the air is when the Acura NSX will go on sale. Jon Ikeda, Acura VP and general manager tells the magazine that meeting with dealers in October will hold the answer. Source: Automobile View full article

-

Acura Delays NSX Production Due To New Engine, Now Coming As 2017 Model

William Maley posted an article in Acura

The long wait for the Acura NSX continues. Automobile reports that Acura has pushed back production from this fall to next Spring due to a change in engine layout. The original plan was to use a naturally-aspirated V6 for the vehicle, but it was decided to add turbochargers to the engine. This has caused Acura to build a bespoke twin-turbo V6 and change the engine layout to a longitudinal configuration. This delay puts the transformation from the NSX being a concept car to production car at about four years. One item that is still up in the air is when the Acura NSX will go on sale. Jon Ikeda, Acura VP and general manager tells the magazine that meeting with dealers in October will hold the answer. Source: Automobile -

G. David Felt Alternative Fuels & Propulsion writer www.CheersandGears.com Connect & Cruise CRATE POWERTRAIN SYSTEMS GM has launched their complete solution packages for older auto's. Including both RWD and 4WD solutions, GM wanted to get these launched with a mail-in rebate for an end of the year present to all motor-heads. GM is offering 12 different combinations including emissions certified E-ROD packages. These packages include a factory tuned engine and transmission with all the electronic control modules, wiring harness and other key components so you can truly strip out the old powertrain and go modern. Engine choices come as follows: LC9 (5.3L) - 315HP available in 2WD, 4WD, and E-ROD LS3 (6.2L) - 430HP available in 2WD and E-ROD LS376 / 480 available in 2WD and 4WD LS376 / 525 available in 2WD LSA (6.2L) - 556HP available 2WD and E-ROD LS7 (7.0L) - 505HP available 2WD Rebates are $500 or $750 depending on package. Connect & Cruise Crate Powertrain Systems Crate Engine Depot pricing Some of the best I have seen around. Make your old dream car, truck or SUV come to life. 1970 Chevelle with a Connect and Cruise package.

- 17 replies

-

- Connect & Cruise

- crate engines

-

(and 5 more)

Tagged with:

-

William Maley Staff Writer - CheersandGears.com October 19, 2013 A new report from Edmunds shines some light on what Buick possibly has in store powertrain-wise for some of their vehicles. A sources says that Buick is planning on offering a diesel engine in their lineup. This is due to Buick and Opel becoming more aligned. Also, diesels have gained more ground in the U.S. thanks to their ability to provide large fuel economy numbers without a massive hit on performance. The source doesn't say which vehicle will get the diesel engine, but Edmunds speculates it will be the Verano since it's closely related to the Chevrolet Cruze which offers a diesel engine. Another source tells Edmunds that Buick is considering adding more power to wildly-popular Encore crossover. The source explained that one of the primary reasons given why prospective buyers would not buy the Encore is the lack of power from the 1.4L turbo-four which produces 138 horsepower. Buick is reportedly scrambling to get a more powerful engine, but there comes a problem with that. Engineers have tried to fit the 2.4L four-cylinder and 2.0L turbo-four, but they don't fit in the Encore's tight engine bay. The source says that GM is now looking at using one of the new 1.6L four-cylinder engines introduced in Europe earlier this year. Source: Edmunds William Maley is a staff writer for Cheers & Gears. He can be reached at [email protected] or you can follow him on twitter at @realmudmonster.

-

William Maley Staff Writer - CheersandGears.com October 19, 2013 A new report from Edmunds shines some light on what Buick possibly has in store powertrain-wise for some of their vehicles. A sources says that Buick is planning on offering a diesel engine in their lineup. This is due to Buick and Opel becoming more aligned. Also, diesels have gained more ground in the U.S. thanks to their ability to provide large fuel economy numbers without a massive hit on performance. The source doesn't say which vehicle will get the diesel engine, but Edmunds speculates it will be the Verano since it's closely related to the Chevrolet Cruze which offers a diesel engine. Another source tells Edmunds that Buick is considering adding more power to wildly-popular Encore crossover. The source explained that one of the primary reasons given why prospective buyers would not buy the Encore is the lack of power from the 1.4L turbo-four which produces 138 horsepower. Buick is reportedly scrambling to get a more powerful engine, but there comes a problem with that. Engineers have tried to fit the 2.4L four-cylinder and 2.0L turbo-four, but they don't fit in the Encore's tight engine bay. The source says that GM is now looking at using one of the new 1.6L four-cylinder engines introduced in Europe earlier this year. Source: Edmunds William Maley is a staff writer for Cheers & Gears. He can be reached at [email protected] or you can follow him on twitter at @realmudmonster. View full article

-

William Maley Staff Writer - CheersandGears.com September 29, 2013 We're just a couple months away from MINI showing off the next-generation Cooper at MINI's factory in Oxford, Great Britain. To keep us interested, MINI has revealed the powertrain lineup and chassis for the Cooper. The standard Cooper will get a new 1.5L turbocharged three-cylinder with 134 horsepower and 162 pound-feet of torque (170 pound-feet for a few seconds with MINI's overboost function). The Cooper S gets a new 2.0L turbocharged four-cylinder with 189 horsepower and 207 pound-feet of torque (221 pound-feet with overboost). These power figures are thanks in part to TwinPower turbocharging and direct injection from BMW. Transmissions are a six-speed manual or automatic. The automatic has a clever trick where it can communicate with the optional navigation system to adapt gear selection to the current route. This sounds similar to what Rolls-Royce is using with the new Wraith. Chassis-wise, the Cooper will stick with the damper strut front suspension and a multi-link rear setup. New is a optional adjustable dampers that offer two settings; normal and sport. Steering is a revised electric system. Source: MINI William Maley is a staff writer for Cheers & Gears. He can be reached at [email protected] you can follow him on twitter at @realmudmonster. Press Release is on Page 2 Innovative technology for typical MINI MOTORING pleasure: New generation of three and four-cylinder engines All-new chassis technology Passive safety, protection for passengers and pedestrians Woodcliff Lake, NJ – September 29, 2013… The latest innovations in drivetrain, chassis and safety will see future MINI models build on their segment-leading position. Since 1959, the unmistakable go-kart feeling has been at the heart of the British marque’s DNA. Today, every member of the MINI family has the combination of agile handling, exemplary efficiency, contemporary comfort and uncompromising safety. With the typical innovative strength expected from a premium manufacturer, MINI seeks to set standards for the future in developing vehicles and technologies that transform driving into a unique motoring experience. A new generation of engines will once again optimize the balance between driving thrills and fuel consumption. Future MINI models will be the first to use both three and four-cylinder engines, not only covering a broader performance spectrum, but also setting new standards in terms of output, performance, comfort and reliability. The quality of the new engines is a direct result of the unique development expertise of the BMW Group in the area of drive technology. Thanks to the brand and model-specific design, they have performance characteristics synonymous with the MINI motoring experience. The advances achieved by MINI in the area of drivetrain technology are characterized by the consistent further development of tried-and-tested design principles and the integration of innovative technology. MINI developers will continue to emphasize sporty, agile handling for all chassis variants. In addition, MINI will introduce electrically adjustable dampers for the first time. The electric control of the damper valves will make it possible to vary the nature of responsiveness to uneven road surfaces. Two characteristic curves will be available for damper adjustment that can be activated at the flip of a switch. Depending on the driver's preferences, a sporty drivetrain setting or something more balanced and comfortable can be selected. The new generation of engines. Maximum motoring fun and the most economical fuel consumption – a two-fold victory in terms of performance and efficiency has helped the latest MINI models to score top marks over their rivals in comparative tests regarding engine technology and driving performance. This is made possible by a new generation of engines and MINIMALISM technologies which will be available in all models as standard. For the first time, the MINI models of the future will use both three and four-cylinder engines that not only cover an even broader range of performance, but also set new standards in terms of output, efficiency, comfort and reliability. Both brand and model-specific design ensures that they have performance characteristics typical of MINI. More power and lower CO2 emissions thanks to MINI TwinPower turbo technology. A common feature of the new drive units is the MINI TwinPower turbo technology, which optimizes both performance and efficiency. In the case of the petrol engines, this technology package includes turbocharging, direct fuel injection, variable camshaft control on the intake and outlet sides (dual VANOS) and, in the more powerful versions, fully variable valve control according to the model of the BMW Group's patented VALVETRONIC system. All-new engines were designed for the transverse configuration typical of the MINI and feature a compact and lightweight design. They also comply with exhaust standard EU6. The engines are equipped with an aluminum crankshaft in a closed-deck configuration. A forged steel crankshaft with integrated balancing shaft drive, weight-optimized piston and forged conrod contributes to the high level of performance within the engine through reduced frictional coefficients. The three-cylinder engines each have a countershaft to enhance smooth operation, while the four-cylinder model has two such shafts that counter-rotate. The cylinder head in all engine variants is made of aluminum. For the market launch of the new drive generation, MINI is presenting a three-cylinder combustion engine that generates an output of 100 kW/134 bhp from a cubic capacity of 1.5 liters and a 141 kW/189 bhp variant of the newly developed four-cylinder combustion engine that has a cubic capacity of 2.0 liters. A new generation of engines with typical MINI performance characteristics. All of the new petrol engines feature spontaneous responsiveness, high torque characteristics and supreme power delivery. The 1.5 litre three-cylinder engine reaches its maximum torque of 220 newton meters at an engine speed of 1,250 rpm; this can be increased briefly to 230 newton meters by means of the overboost function. The 141 kW/189 bhp four-cylinder model actually achieves a torque of 280 newton meters with the same engine speed (300 nm with overboost). The maximum speed of all new petrol engines is 6,500 rpm. The engine's sporty character is favored by the position of the turbocharger integrated in the exhaust manifold. The short path of the exhaust stream enables the charging system to be activated promptly and effectively. In addition, the emissions pattern of the engines is optimized by the positioning of the catalytic converter and an electronically regulated waste gate. An efficient and precisely dosed fuel supply system facilitates direct injection with centrally positioned injectors between the valves and directly next to the spark plugs. The electronic control for camshaft positioning and the stroke of the intake valves are further technological elements that optimize the responsiveness and the consumption and emissions readings of the new petrol engines for MINI. Newly developed manual and automatic gearboxes will further contribute to the intense motoring pleasure that MINI has to offer, and will enhance the efficiency of the drive technology. The new manual gearboxes feature an innovative gear sensor which adapts the engine speed when shifting gears. This permits fast and sporty shifting with always the right engine speed available during gear shifts. The automatic start-stop function can also be used in future MINI models in conjunction with the automatic gearbox, avoiding unnecessary fuel consumption when stopped at junctions or when caught in heavy traffic. For cars equipped with a navigation system, gear selection can be adapted to the current route. This way, the suitable gear is selected before reaching junctions or before cornering. Chassis Technology. Thanks to the continued optimization in the areas of wheel suspension, spring system, damping, steering and braking, motoring is set to become even more enjoyable in future MINI models. In combination with the features so characteristic of any MINI, such as the vehicle's low centre of gravity, wide track gauge, short overhangs, transverse engine, rigid bodywork and intelligent lightweight design, innovative solutions in the chassis area make for even more precise and sporty handling. The agility that characterizes all MINIs is also combined with further advances in the area of driving comfort. This is the first time that MINI is to offer electrically adjustable dampers that can be used to optimize sportiness and driving comfort. Tried-and-tested construction principle, completely redeveloped components. The complete redesign of the chassis for future MINI models continues to focus on the tried-and-tested structure of the single-link spring strut axle at the front, and the multi-link rear axle - unique among MINI's competitors. It also includes component optimizations in terms of material choice and geometry. The dampers on the front and rear axles are uncoupled from the bodywork by means of complex struts. In combination with the reduction of the unsprung inertial masses, this makes it possible to increase both agility and driving comfort. Newly developed and aerodynamically optimised light alloy wheels are manufactured in a forging process requiring the use of less material. In its latest incarnation, the front single-link spring strut axle features increased component rigidity. In combination with a modified axial kinematic movement, this creates ideal conditions for particularly agile manoeuvrability and steering control that is largely freed from the influence of the drive mechanism. The wider track gauge also makes a further contribution to optimizing sporty characteristics. Consistency in lightweight design also influenced driving performance. The use of aluminum in the pivot bearing and high tensile steels in the front axle bearing and in the transverse rocker arms reduces the unsprung inertial masses. The innovative torque roll axial bearing enables both agility and comfort to be tangibly increased. This component consists of an engine and a transmission bearing that together absorb the weight of the engine and also support the torque in conjunction with the engine swivel support. The engine block is hydraulically attenuated, further enhancing the increase in comfort because this design prevents the engine from surging under the influence of uneven road surfaces. By further developing the multi-link rear axle, MINI is building on its unique position in the competitive field. Key changes – wider track gauge, the use of high-strength steels and greater rigidity in the wheel suspension – take place in tandem with the modifications to the front axle. The spatial design of the rear axle also leads to improved entry comfort and to more space in the rear as well as a larger luggage compartment volume which is also easier to load. More precise, more comfortable: electromechanical power steering. The next generation of the EPS (Electronic Power Steering) used for MINI models offers speed-dependent support for the steering force. In the future it will take less steering force to operate this, while the system will also meet the requirements for the use of a parking assist function. The further development of the steering system will promote agility, driving safety and comfort in equal measure. Thanks to the complex wheel suspension system, the steering ratio can be implemented very directly. Likewise, the optimization of the front axle has a direct impact on the steering, as it facilitates a sensitive steering style when negotiating bends in a sporty style. This effect is further enhanced by the use of so-called torque steer compensation. This torque steering compensation counteracts a tendency towards self-steering in powerful front-wheel drive vehicles due to differences in torque between the right and left front wheels. In the future, active rotational damping will provide for gentler and therefore more precisely controllable vehicle reactions in rapid evasion manoeuvres and when negotiating particularly sporty bends. Advanced brake system for more comfort and security. Another important contribution to motoring pleasure is derived from the improvements in the function and weight of the brake system, which is more closely tailored to the specific models. The new system impresses with its excellent durability with low unsprung inertial masses. This results in greater comfort, more precise dosability and a longer service life. The efficiency of the MINI can also be increased through targeted innovations in the brake system. Thus, optimized coatings help to reduce the residual braking momentum, thereby enhancing the vehicle's rolling friction. Excellent long-lasting properties are achieved through improved surface protection on the disc brake chamber and brake callipers. Another plus point is the optimization of the brake cooling system through refined brake protection plates and a redesigned brake cooling shaft. A first for MINI: adjustable dampers. In an effort to emphasize the MINI character even more, the spring and damper adjustment will be optimized. On the front axle, spring struts made of aluminum and steel and two-pipe compression dampers with coated pistons and a degressive damper characteristic curve are used. The support bearings on the front and rear axles will have three paths in future. The characteristic curves of the support bearing and additional springs have also been optimized on a functional basis, as have the helical springs installed on both axes. The stabilisers on the front and rear axles have holdings bearings and will have a tubular design, helping to reduce weight in the chassis area. In addition, MINI will be introducing adjustable dampers for the first time. The electric control of the damper valves allows the characteristic response to uneven road surface to be varied. Two characteristic curves are available for adjusting the damper and these can be activated at the flip of a switch. The traction and compression level in the shock absorber can be adjusted by selecting the appropriate setting. Depending on the driver's preferences, it is possible to choose either a sporty or a balanced, comfortable chassis. This means that it is possible to enjoy greater driving comfort in poor road conditions or a sporty driving style on an even road surface. Passive safety, protection for passengers and pedestrians. Premium vehicles by MINI hold an excellent position within their vehicle class not just in terms of motoring pleasure, but also in the area of passenger protection. In the event of a collision, precisely defined support structures and generously proportioned crumple zones help to protect the passenger cell while highly efficient restraint systems offer MINI passengers optimum protection in all types of crashes. Top scores in international crash tests confirm the effectiveness of the overall concept for maximum passive safety, which is under continuous development for new models to ensure that the latest standards are met. In addition, innovative solutions in the area of pedestrian protection are also being developed for future MINI models, helping to reduce the risk of injury for other road users. Reduced weight and increased safety thanks to intelligent lightweight construction. The focus of developments in the body area is on structural improvements that have a positive influence on both driving features and crash performance. Intelligent lightweight construction enables MINI to combine the reduction of weight with an increase in rigidity and this promotes both agility and passenger protection. The use of second generation high-strength multi-phase steels plays a key role. Their excellent forming properties allow for much more complex structures than would be possible with conventional materials, while still permitting no compromise on strength. Parts that are of particular relevance to structural rigidity are made from micro-alloyed steels. In addition, hot-formed steels are used in the safety-related zones. So-called tailored welded blanks and tailored rolled blanks also contribute to the optimization of weight. Welded and rolled sheet metal joints are widely used for the first time in cars from the small vehicle segment. The reinforcement of the B pillars with a coating of galvanised, hot-formed steel, which acts as a cathodic anti-corrosion finish, means that additional, weight-increasing measures could be dropped. Despite the reduced weight, the intelligent mix of materials for the highly resilient support structures in the front and rear and in the roof and side frame. In the event of the vehicle rolling over, the reinforced pillars and roof supports secure the survival space of the passengers even more intensively than ever. Reinforced structures in the B pillar and sill area, high-strength side impact bars in the doors and stable seat braces will further minimize the degree of deformation and the speed of intrusion in the event of a side impact. This concept establishes the right conditions for maintaining the passenger cell as a survival space in a wide variety of accident scenarios and forms the basis for the high level of effectiveness of the restraint systems. The integrated safety electronics ensure that the triggering of the airbag and belt systems is adapted to the type and severity of the accident. The coordinated interaction of all components ensures the best possible protection, irrespective of the position of the passengers at the time of impact. Crumple elements on the front for extensive pedestrian protection. The front section of future MINI models will have extra crumple elements. In addition to the yielding sections of the engine cover, a shock absorber between the bumper bracket and the cladding is intended to reduce the risk of injury. The pedestrian protection system will also be part of the standard equipment supplied with new MINI models. View full article

-

William Maley Staff Writer - CheersandGears.com September 29, 2013 We're just a couple months away from MINI showing off the next-generation Cooper at MINI's factory in Oxford, Great Britain. To keep us interested, MINI has revealed the powertrain lineup and chassis for the Cooper. The standard Cooper will get a new 1.5L turbocharged three-cylinder with 134 horsepower and 162 pound-feet of torque (170 pound-feet for a few seconds with MINI's overboost function). The Cooper S gets a new 2.0L turbocharged four-cylinder with 189 horsepower and 207 pound-feet of torque (221 pound-feet with overboost). These power figures are thanks in part to TwinPower turbocharging and direct injection from BMW. Transmissions are a six-speed manual or automatic. The automatic has a clever trick where it can communicate with the optional navigation system to adapt gear selection to the current route. This sounds similar to what Rolls-Royce is using with the new Wraith. Chassis-wise, the Cooper will stick with the damper strut front suspension and a multi-link rear setup. New is a optional adjustable dampers that offer two settings; normal and sport. Steering is a revised electric system. Source: MINI William Maley is a staff writer for Cheers & Gears. He can be reached at [email protected] you can follow him on twitter at @realmudmonster. Press Release is on Page 2 Innovative technology for typical MINI MOTORING pleasure: New generation of three and four-cylinder engines All-new chassis technology Passive safety, protection for passengers and pedestrians Woodcliff Lake, NJ – September 29, 2013… The latest innovations in drivetrain, chassis and safety will see future MINI models build on their segment-leading position. Since 1959, the unmistakable go-kart feeling has been at the heart of the British marque’s DNA. Today, every member of the MINI family has the combination of agile handling, exemplary efficiency, contemporary comfort and uncompromising safety. With the typical innovative strength expected from a premium manufacturer, MINI seeks to set standards for the future in developing vehicles and technologies that transform driving into a unique motoring experience. A new generation of engines will once again optimize the balance between driving thrills and fuel consumption. Future MINI models will be the first to use both three and four-cylinder engines, not only covering a broader performance spectrum, but also setting new standards in terms of output, performance, comfort and reliability. The quality of the new engines is a direct result of the unique development expertise of the BMW Group in the area of drive technology. Thanks to the brand and model-specific design, they have performance characteristics synonymous with the MINI motoring experience. The advances achieved by MINI in the area of drivetrain technology are characterized by the consistent further development of tried-and-tested design principles and the integration of innovative technology. MINI developers will continue to emphasize sporty, agile handling for all chassis variants. In addition, MINI will introduce electrically adjustable dampers for the first time. The electric control of the damper valves will make it possible to vary the nature of responsiveness to uneven road surfaces. Two characteristic curves will be available for damper adjustment that can be activated at the flip of a switch. Depending on the driver's preferences, a sporty drivetrain setting or something more balanced and comfortable can be selected. The new generation of engines. Maximum motoring fun and the most economical fuel consumption – a two-fold victory in terms of performance and efficiency has helped the latest MINI models to score top marks over their rivals in comparative tests regarding engine technology and driving performance. This is made possible by a new generation of engines and MINIMALISM technologies which will be available in all models as standard. For the first time, the MINI models of the future will use both three and four-cylinder engines that not only cover an even broader range of performance, but also set new standards in terms of output, efficiency, comfort and reliability. Both brand and model-specific design ensures that they have performance characteristics typical of MINI. More power and lower CO2 emissions thanks to MINI TwinPower turbo technology. A common feature of the new drive units is the MINI TwinPower turbo technology, which optimizes both performance and efficiency. In the case of the petrol engines, this technology package includes turbocharging, direct fuel injection, variable camshaft control on the intake and outlet sides (dual VANOS) and, in the more powerful versions, fully variable valve control according to the model of the BMW Group's patented VALVETRONIC system. All-new engines were designed for the transverse configuration typical of the MINI and feature a compact and lightweight design. They also comply with exhaust standard EU6. The engines are equipped with an aluminum crankshaft in a closed-deck configuration. A forged steel crankshaft with integrated balancing shaft drive, weight-optimized piston and forged conrod contributes to the high level of performance within the engine through reduced frictional coefficients. The three-cylinder engines each have a countershaft to enhance smooth operation, while the four-cylinder model has two such shafts that counter-rotate. The cylinder head in all engine variants is made of aluminum. For the market launch of the new drive generation, MINI is presenting a three-cylinder combustion engine that generates an output of 100 kW/134 bhp from a cubic capacity of 1.5 liters and a 141 kW/189 bhp variant of the newly developed four-cylinder combustion engine that has a cubic capacity of 2.0 liters. A new generation of engines with typical MINI performance characteristics. All of the new petrol engines feature spontaneous responsiveness, high torque characteristics and supreme power delivery. The 1.5 litre three-cylinder engine reaches its maximum torque of 220 newton meters at an engine speed of 1,250 rpm; this can be increased briefly to 230 newton meters by means of the overboost function. The 141 kW/189 bhp four-cylinder model actually achieves a torque of 280 newton meters with the same engine speed (300 nm with overboost). The maximum speed of all new petrol engines is 6,500 rpm. The engine's sporty character is favored by the position of the turbocharger integrated in the exhaust manifold. The short path of the exhaust stream enables the charging system to be activated promptly and effectively. In addition, the emissions pattern of the engines is optimized by the positioning of the catalytic converter and an electronically regulated waste gate. An efficient and precisely dosed fuel supply system facilitates direct injection with centrally positioned injectors between the valves and directly next to the spark plugs. The electronic control for camshaft positioning and the stroke of the intake valves are further technological elements that optimize the responsiveness and the consumption and emissions readings of the new petrol engines for MINI. Newly developed manual and automatic gearboxes will further contribute to the intense motoring pleasure that MINI has to offer, and will enhance the efficiency of the drive technology. The new manual gearboxes feature an innovative gear sensor which adapts the engine speed when shifting gears. This permits fast and sporty shifting with always the right engine speed available during gear shifts. The automatic start-stop function can also be used in future MINI models in conjunction with the automatic gearbox, avoiding unnecessary fuel consumption when stopped at junctions or when caught in heavy traffic. For cars equipped with a navigation system, gear selection can be adapted to the current route. This way, the suitable gear is selected before reaching junctions or before cornering. Chassis Technology. Thanks to the continued optimization in the areas of wheel suspension, spring system, damping, steering and braking, motoring is set to become even more enjoyable in future MINI models. In combination with the features so characteristic of any MINI, such as the vehicle's low centre of gravity, wide track gauge, short overhangs, transverse engine, rigid bodywork and intelligent lightweight design, innovative solutions in the chassis area make for even more precise and sporty handling. The agility that characterizes all MINIs is also combined with further advances in the area of driving comfort. This is the first time that MINI is to offer electrically adjustable dampers that can be used to optimize sportiness and driving comfort. Tried-and-tested construction principle, completely redeveloped components. The complete redesign of the chassis for future MINI models continues to focus on the tried-and-tested structure of the single-link spring strut axle at the front, and the multi-link rear axle - unique among MINI's competitors. It also includes component optimizations in terms of material choice and geometry. The dampers on the front and rear axles are uncoupled from the bodywork by means of complex struts. In combination with the reduction of the unsprung inertial masses, this makes it possible to increase both agility and driving comfort. Newly developed and aerodynamically optimised light alloy wheels are manufactured in a forging process requiring the use of less material. In its latest incarnation, the front single-link spring strut axle features increased component rigidity. In combination with a modified axial kinematic movement, this creates ideal conditions for particularly agile manoeuvrability and steering control that is largely freed from the influence of the drive mechanism. The wider track gauge also makes a further contribution to optimizing sporty characteristics. Consistency in lightweight design also influenced driving performance. The use of aluminum in the pivot bearing and high tensile steels in the front axle bearing and in the transverse rocker arms reduces the unsprung inertial masses. The innovative torque roll axial bearing enables both agility and comfort to be tangibly increased. This component consists of an engine and a transmission bearing that together absorb the weight of the engine and also support the torque in conjunction with the engine swivel support. The engine block is hydraulically attenuated, further enhancing the increase in comfort because this design prevents the engine from surging under the influence of uneven road surfaces. By further developing the multi-link rear axle, MINI is building on its unique position in the competitive field. Key changes – wider track gauge, the use of high-strength steels and greater rigidity in the wheel suspension – take place in tandem with the modifications to the front axle. The spatial design of the rear axle also leads to improved entry comfort and to more space in the rear as well as a larger luggage compartment volume which is also easier to load. More precise, more comfortable: electromechanical power steering. The next generation of the EPS (Electronic Power Steering) used for MINI models offers speed-dependent support for the steering force. In the future it will take less steering force to operate this, while the system will also meet the requirements for the use of a parking assist function. The further development of the steering system will promote agility, driving safety and comfort in equal measure. Thanks to the complex wheel suspension system, the steering ratio can be implemented very directly. Likewise, the optimization of the front axle has a direct impact on the steering, as it facilitates a sensitive steering style when negotiating bends in a sporty style. This effect is further enhanced by the use of so-called torque steer compensation. This torque steering compensation counteracts a tendency towards self-steering in powerful front-wheel drive vehicles due to differences in torque between the right and left front wheels. In the future, active rotational damping will provide for gentler and therefore more precisely controllable vehicle reactions in rapid evasion manoeuvres and when negotiating particularly sporty bends. Advanced brake system for more comfort and security. Another important contribution to motoring pleasure is derived from the improvements in the function and weight of the brake system, which is more closely tailored to the specific models. The new system impresses with its excellent durability with low unsprung inertial masses. This results in greater comfort, more precise dosability and a longer service life. The efficiency of the MINI can also be increased through targeted innovations in the brake system. Thus, optimized coatings help to reduce the residual braking momentum, thereby enhancing the vehicle's rolling friction. Excellent long-lasting properties are achieved through improved surface protection on the disc brake chamber and brake callipers. Another plus point is the optimization of the brake cooling system through refined brake protection plates and a redesigned brake cooling shaft. A first for MINI: adjustable dampers. In an effort to emphasize the MINI character even more, the spring and damper adjustment will be optimized. On the front axle, spring struts made of aluminum and steel and two-pipe compression dampers with coated pistons and a degressive damper characteristic curve are used. The support bearings on the front and rear axles will have three paths in future. The characteristic curves of the support bearing and additional springs have also been optimized on a functional basis, as have the helical springs installed on both axes. The stabilisers on the front and rear axles have holdings bearings and will have a tubular design, helping to reduce weight in the chassis area. In addition, MINI will be introducing adjustable dampers for the first time. The electric control of the damper valves allows the characteristic response to uneven road surface to be varied. Two characteristic curves are available for adjusting the damper and these can be activated at the flip of a switch. The traction and compression level in the shock absorber can be adjusted by selecting the appropriate setting. Depending on the driver's preferences, it is possible to choose either a sporty or a balanced, comfortable chassis. This means that it is possible to enjoy greater driving comfort in poor road conditions or a sporty driving style on an even road surface. Passive safety, protection for passengers and pedestrians. Premium vehicles by MINI hold an excellent position within their vehicle class not just in terms of motoring pleasure, but also in the area of passenger protection. In the event of a collision, precisely defined support structures and generously proportioned crumple zones help to protect the passenger cell while highly efficient restraint systems offer MINI passengers optimum protection in all types of crashes. Top scores in international crash tests confirm the effectiveness of the overall concept for maximum passive safety, which is under continuous development for new models to ensure that the latest standards are met. In addition, innovative solutions in the area of pedestrian protection are also being developed for future MINI models, helping to reduce the risk of injury for other road users. Reduced weight and increased safety thanks to intelligent lightweight construction. The focus of developments in the body area is on structural improvements that have a positive influence on both driving features and crash performance. Intelligent lightweight construction enables MINI to combine the reduction of weight with an increase in rigidity and this promotes both agility and passenger protection. The use of second generation high-strength multi-phase steels plays a key role. Their excellent forming properties allow for much more complex structures than would be possible with conventional materials, while still permitting no compromise on strength. Parts that are of particular relevance to structural rigidity are made from micro-alloyed steels. In addition, hot-formed steels are used in the safety-related zones. So-called tailored welded blanks and tailored rolled blanks also contribute to the optimization of weight. Welded and rolled sheet metal joints are widely used for the first time in cars from the small vehicle segment. The reinforcement of the B pillars with a coating of galvanised, hot-formed steel, which acts as a cathodic anti-corrosion finish, means that additional, weight-increasing measures could be dropped. Despite the reduced weight, the intelligent mix of materials for the highly resilient support structures in the front and rear and in the roof and side frame. In the event of the vehicle rolling over, the reinforced pillars and roof supports secure the survival space of the passengers even more intensively than ever. Reinforced structures in the B pillar and sill area, high-strength side impact bars in the doors and stable seat braces will further minimize the degree of deformation and the speed of intrusion in the event of a side impact. This concept establishes the right conditions for maintaining the passenger cell as a survival space in a wide variety of accident scenarios and forms the basis for the high level of effectiveness of the restraint systems. The integrated safety electronics ensure that the triggering of the airbag and belt systems is adapted to the type and severity of the accident. The coordinated interaction of all components ensures the best possible protection, irrespective of the position of the passengers at the time of impact. Crumple elements on the front for extensive pedestrian protection. The front section of future MINI models will have extra crumple elements. In addition to the yielding sections of the engine cover, a shock absorber between the bumper bracket and the cladding is intended to reduce the risk of injury. The pedestrian protection system will also be part of the standard equipment supplied with new MINI models.

- 2 comments

-

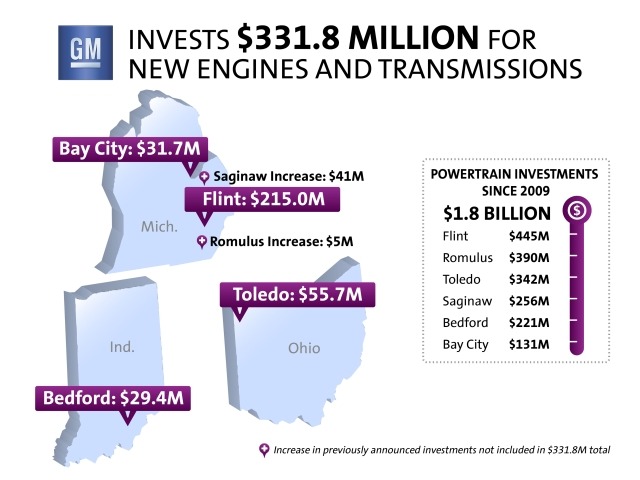

By William Maley Staff Writer - CheersandGears.com April 4, 2013 General Motors announced today a new investment of $331.8 million in four manufacturing sites to produce more fuel-efficient engines and transmissions. GM said in a press release today that some parts of the investment will help prepare its factories to produce a new eight-speed automatic transmission and increase capacity for an existing six-speed gearbox. Other parts will go towards support the production of a new V6 engine (no details given in the release) and a new EcoTec engine that will be part of a new family of 3- and 4-cylinder variants with displacements ranging from 1.0 to 1.5 liters.. Here is a breakdown of the investments: $215 million in Flint Engine Operations $55.7 million in Toledo Transmission Operations $31.7 million in Bay City Powertrain $29.4 million in Bedford Castings GM will also increase a previous $600 million investment in its Saginaw Metal Castings Operations and Romulus Engine Operations by $46 million. Source: General Motors Press Release is on Page 2 GM Invests $332 Million for New Fuel-Efficient Powertrains Brings to $1.2 billion amount of U.S. facility investment announced this year DETROIT – General Motors Co. will invest nearly $332 million in four manufacturing sites to produce more fuel-efficient engines and transmissions, demonstrating GM's commitment to deliver what customers want: technology-driven performance and fewer trips to the pump. The investments – announced today at GM plants in Flint and Bay City, Mich.; Toledo, Ohio, and Bedford, Ind. – will support production of a new Ecotec small gas engine, a new V6 engine, 8-speed transmission, and tooling for an existing 6-speed transmission. GM also is increasing previously announced powertrain investment in plants in Romulus and Saginaw, Mich., to $646 million – an increase of $46 million – to support production of the new V6 engine. Since 2009, GM has announced nearly $1.8 billion of investments for the six Powertrain facilities. “We are investing in technologies and manufacturing capabilities that produce high-quality, fuel-efficient vehicles and components for our customers,” said Diana Tremblay, vice president of GM North American Manufacturing. “Today’s announcement demonstrates GM’s commitment to growing the business and strengthening the plant communities where we receive so much support.” Combined, the two investments will retain about 1,650 jobs at the six facilities. “The selection of these plants and the opportunity for the United Auto Workers to build the next generation of engines and transmissions reflects the great efforts of our work force,” said UAW Vice President Joe Ashton, who directs the union’s GM department. “This investment goes a long way to ensuring GM remains a marketplace leader and our members can continue to support and share in the company’s growth.” GM’s newly announced $331.8 million investment includes: $215 million in Flint Engine Operations for a new small Ecotec gasoline engine, which is part of a new family of engines that includes 3- and 4-cylinder variants with displacements ranging from 1.0 to 1.5 liters. Details of what variants the plant will build will be announced later. The plant will also upgrade tooling for its current V6 engine. $55.7 million in Toledo Transmission Operations for increased capacity and tooling to produce an all-new, advanced 8-speed automatic transmission and an existing 6-speed transmission. The Toledo-based 8-speed will be used in numerous GM vehicles by the end of 2016. $31.7 million in Bay City Powertrain including $19.2 million to produce components for a new V6 engine and $12.5 million to produce components for the small Ecotec gasoline engine. $29.4 million in Bedford Castings including $19 million to produce components for the small gas engine and $10.4 million to produce components for the new 8-speed and existing 6-speed transmissions. The additional $46 million brings the total to $646 million for the V6 project including: A $41 million increase to $256 million for Saginaw Metal Castings Operations to produce castings for the new V6 engine. A $5 million increase to $390 million for Romulus Engine Operations to build the new V6 engines. The new small Ecotec gasoline engine is part of a global engine family that could top 2 million engines a year by the end of the decade, based on production in Flint and other locations around the world. The new engines will offer improved fuel economy, higher quality, better performance and reduced carbon dioxide emissions. The 8-speed automatic transmission will assist in improved fuel economy and performance. Details about the new V6 engine program will be announced later. Since 2009, GM has announced investments of more than $8.5 billion in its U.S. operations - $1.2 billion so far in 2013 – creating or retaining more than 24,700 jobs. View full article

- 4 replies

-

- General Motors

- Investments

-

(and 1 more)

Tagged with:

-

General Motors Announces A $332M Powertrain Investment

William Maley posted an article in General Motors

By William Maley Staff Writer - CheersandGears.com April 4, 2013 General Motors announced today a new investment of $331.8 million in four manufacturing sites to produce more fuel-efficient engines and transmissions. GM said in a press release today that some parts of the investment will help prepare its factories to produce a new eight-speed automatic transmission and increase capacity for an existing six-speed gearbox. Other parts will go towards support the production of a new V6 engine (no details given in the release) and a new EcoTec engine that will be part of a new family of 3- and 4-cylinder variants with displacements ranging from 1.0 to 1.5 liters.. Here is a breakdown of the investments: $215 million in Flint Engine Operations $55.7 million in Toledo Transmission Operations $31.7 million in Bay City Powertrain $29.4 million in Bedford Castings GM will also increase a previous $600 million investment in its Saginaw Metal Castings Operations and Romulus Engine Operations by $46 million. Source: General Motors Press Release is on Page 2 GM Invests $332 Million for New Fuel-Efficient Powertrains Brings to $1.2 billion amount of U.S. facility investment announced this year DETROIT – General Motors Co. will invest nearly $332 million in four manufacturing sites to produce more fuel-efficient engines and transmissions, demonstrating GM's commitment to deliver what customers want: technology-driven performance and fewer trips to the pump. The investments – announced today at GM plants in Flint and Bay City, Mich.; Toledo, Ohio, and Bedford, Ind. – will support production of a new Ecotec small gas engine, a new V6 engine, 8-speed transmission, and tooling for an existing 6-speed transmission. GM also is increasing previously announced powertrain investment in plants in Romulus and Saginaw, Mich., to $646 million – an increase of $46 million – to support production of the new V6 engine. Since 2009, GM has announced nearly $1.8 billion of investments for the six Powertrain facilities. “We are investing in technologies and manufacturing capabilities that produce high-quality, fuel-efficient vehicles and components for our customers,” said Diana Tremblay, vice president of GM North American Manufacturing. “Today’s announcement demonstrates GM’s commitment to growing the business and strengthening the plant communities where we receive so much support.” Combined, the two investments will retain about 1,650 jobs at the six facilities. “The selection of these plants and the opportunity for the United Auto Workers to build the next generation of engines and transmissions reflects the great efforts of our work force,” said UAW Vice President Joe Ashton, who directs the union’s GM department. “This investment goes a long way to ensuring GM remains a marketplace leader and our members can continue to support and share in the company’s growth.” GM’s newly announced $331.8 million investment includes: $215 million in Flint Engine Operations for a new small Ecotec gasoline engine, which is part of a new family of engines that includes 3- and 4-cylinder variants with displacements ranging from 1.0 to 1.5 liters. Details of what variants the plant will build will be announced later. The plant will also upgrade tooling for its current V6 engine. $55.7 million in Toledo Transmission Operations for increased capacity and tooling to produce an all-new, advanced 8-speed automatic transmission and an existing 6-speed transmission. The Toledo-based 8-speed will be used in numerous GM vehicles by the end of 2016. $31.7 million in Bay City Powertrain including $19.2 million to produce components for a new V6 engine and $12.5 million to produce components for the small Ecotec gasoline engine. $29.4 million in Bedford Castings including $19 million to produce components for the small gas engine and $10.4 million to produce components for the new 8-speed and existing 6-speed transmissions. The additional $46 million brings the total to $646 million for the V6 project including: A $41 million increase to $256 million for Saginaw Metal Castings Operations to produce castings for the new V6 engine. A $5 million increase to $390 million for Romulus Engine Operations to build the new V6 engines. The new small Ecotec gasoline engine is part of a global engine family that could top 2 million engines a year by the end of the decade, based on production in Flint and other locations around the world. The new engines will offer improved fuel economy, higher quality, better performance and reduced carbon dioxide emissions. The 8-speed automatic transmission will assist in improved fuel economy and performance. Details about the new V6 engine program will be announced later. Since 2009, GM has announced investments of more than $8.5 billion in its U.S. operations - $1.2 billion so far in 2013 – creating or retaining more than 24,700 jobs.- 4 comments

-

- General Motors

- Investments

-

(and 1 more)

Tagged with: