Search the Community

Showing results for tags 'Plant'.

-

GM Orion getting $300 Million Upgrade; New Electric Chevrolet

Drew Dowdell posted an article in General Motors

GM Announced this morning that the company will be investing $300 million and adding 400 jobs at its Orion Township, Michigan assembly plant. The investment will go towards facilities to produce a new electric vehicle for the Chevrolet brand. The new vehicle will be the second such vehicle, after the Cadillac EV Crossover, to be built on GM's new BEV3 platform, an advance version of the same platform that underpins the Chevrolet Bolt EV. The Orion plant currently builds the Chevrolet Sonic, Chevrolet Bolt EV, and the Cruise AV test vehicles. There are about 880 hourly and 130 salary employees working there. Along with the investment announcement for Orion, GM is announcing another $1.8 billion in U.S. manufacturing. This comes on the heels of the closure of the Lordstown assembly plant in Eastern Ohio. The plant was the subject of a series of tweets by the President in an attempt to get GM to either sell the plant or quickly reopen it. GM has said that it has 2,700 job openings available for the 2,800 employees that have been displaced by the recent idling of 5 of its facilities.- 2 comments

-

- electric vehicle

- ev

-

(and 4 more)

Tagged with:

-

GM Announced this morning that the company will be investing $300 million and adding 400 jobs at its Orion Township, Michigan assembly plant. The investment will go towards facilities to produce a new electric vehicle for the Chevrolet brand. The new vehicle will be the second such vehicle, after the Cadillac EV Crossover, to be built on GM's new BEV3 platform, an advance version of the same platform that underpins the Chevrolet Bolt EV. The Orion plant currently builds the Chevrolet Sonic, Chevrolet Bolt EV, and the Cruise AV test vehicles. There are about 880 hourly and 130 salary employees working there. Along with the investment announcement for Orion, GM is announcing another $1.8 billion in U.S. manufacturing. This comes on the heels of the closure of the Lordstown assembly plant in Eastern Ohio. The plant was the subject of a series of tweets by the President in an attempt to get GM to either sell the plant or quickly reopen it. GM has said that it has 2,700 job openings available for the 2,800 employees that have been displaced by the recent idling of 5 of its facilities. View full article

- 2 replies

-

- electric vehicle

- ev

-

(and 4 more)

Tagged with:

-

Ford will be temporarily shutting down production lines at five of their North American plants to help cut down on the inventory of slow-selling models. According to Automotive News, Ford will be shutting down both of their plants in Mexico. The Cuautitlan assembly plant, which is home to the Fiesta will be down for three weeks. Hermosillo which builds the Fusion and Lincoln MKZ will take a two-week break. In the U.S., Flat Rock (Mustang and Continental) and the Transit production line at Kansas City will also be down for two weeks. Michigan Assembly in Wayne will be down for just a week. It is unknown when the shut downs will begin. "We are continuing to match production with customer demand, as we always do, and we are on track for our dealer inventories to remain at planned levels by year-end," a Ford spokeswoman said in an email. At the start of this month, Ford had an 87-day supply of Fusions, 103-day supply of Transits, 111-day supply of Mustangs, and a 162-day supply of Continentals. Automakers try to shoot for a 65 to 70-day supply of vehicles. Source: Automotive News (Subscription Required), Reuters

-

Ford will be temporarily shutting down production lines at five of their North American plants to help cut down on the inventory of slow-selling models. According to Automotive News, Ford will be shutting down both of their plants in Mexico. The Cuautitlan assembly plant, which is home to the Fiesta will be down for three weeks. Hermosillo which builds the Fusion and Lincoln MKZ will take a two-week break. In the U.S., Flat Rock (Mustang and Continental) and the Transit production line at Kansas City will also be down for two weeks. Michigan Assembly in Wayne will be down for just a week. It is unknown when the shut downs will begin. "We are continuing to match production with customer demand, as we always do, and we are on track for our dealer inventories to remain at planned levels by year-end," a Ford spokeswoman said in an email. At the start of this month, Ford had an 87-day supply of Fusions, 103-day supply of Transits, 111-day supply of Mustangs, and a 162-day supply of Continentals. Automakers try to shoot for a 65 to 70-day supply of vehicles. Source: Automotive News (Subscription Required), Reuters View full article

-

Only a few weeks ago, Toyota and Mazda surprised everyone by announcing a new alliance. The two would collaborate on a number of projects including a $1.6 billion assembly plant, possibly bringing 4,000 new jobs. At the time, the two automakers haven't decided where the plant would go, which sent various states in a frenzy. A report from the Detroit Free Press has learned that the two have sent out a blind request for proposals from states in Midwest, mid-Atlantic and South. Sources tell the paper that the request was from an unidentified employer that was considering options for a new project known as 'Project Mitt'. State officials have sent preliminary proposals that include potential tax incentives, job training programs, and investments in infrastructure. Opportunities like this are very rare and states are pulling all of the stops out to land this plant. “You have to be able to punch the ticket. You have to be able to say you’ve got the workforce, you’ve got the land, you’ve got the transportation systems and rail spurs, community college and education and a place where people want to live,” said Kristin Dziczek, director of industry, labor and economics at the Center for Automotive Research. “Once you’ve got all that, tax incentives come into play.” We recommend checking out the Free Press' report as it lists the states in contention from Alabama to Texas with pros and cons. Source: Detroit Free Press

-

Only a few weeks ago, Toyota and Mazda surprised everyone by announcing a new alliance. The two would collaborate on a number of projects including a $1.6 billion assembly plant, possibly bringing 4,000 new jobs. At the time, the two automakers haven't decided where the plant would go, which sent various states in a frenzy. A report from the Detroit Free Press has learned that the two have sent out a blind request for proposals from states in Midwest, mid-Atlantic and South. Sources tell the paper that the request was from an unidentified employer that was considering options for a new project known as 'Project Mitt'. State officials have sent preliminary proposals that include potential tax incentives, job training programs, and investments in infrastructure. Opportunities like this are very rare and states are pulling all of the stops out to land this plant. “You have to be able to punch the ticket. You have to be able to say you’ve got the workforce, you’ve got the land, you’ve got the transportation systems and rail spurs, community college and education and a place where people want to live,” said Kristin Dziczek, director of industry, labor and economics at the Center for Automotive Research. “Once you’ve got all that, tax incentives come into play.” We recommend checking out the Free Press' report as it lists the states in contention from Alabama to Texas with pros and cons. Source: Detroit Free Press View full article

-

Whenever the Corvette plant closes it doors for public tours for a certain amount of time, it usually means some big change is coming to the model. The Bowling Green Daily News reports that starting next month, GM will suspend plant tours for 18 months. National Corvette Museum Marketing and Communications Manager, Katie Frassinelli tells the paper the suspension is for a reconfiguration of the assembly line and a new paint shop. “The new paint shop at the plant has to be tied into the existing assembly line. The old paint shop is on the opposite side of the plant,” said Frassinelli. It should be noted this is the longest time that the plant tour has been suspended. Unsurprisingly, this announcement has caused many to wonder if the change is somehow related to the long-rumored mid-engined Corvette. Speculation has it that the model will debut at next year's Detroit Auto Show. Source: Bowling Green Daily News View full article

- 9 replies

-

- bowling green

- chevrolet corvette

-

(and 2 more)

Tagged with:

-

Corvette Plant Closes Their Doors To the Public for 18 Months

William Maley posted an article in Chevrolet

Whenever the Corvette plant closes it doors for public tours for a certain amount of time, it usually means some big change is coming to the model. The Bowling Green Daily News reports that starting next month, GM will suspend plant tours for 18 months. National Corvette Museum Marketing and Communications Manager, Katie Frassinelli tells the paper the suspension is for a reconfiguration of the assembly line and a new paint shop. “The new paint shop at the plant has to be tied into the existing assembly line. The old paint shop is on the opposite side of the plant,” said Frassinelli. It should be noted this is the longest time that the plant tour has been suspended. Unsurprisingly, this announcement has caused many to wonder if the change is somehow related to the long-rumored mid-engined Corvette. Speculation has it that the model will debut at next year's Detroit Auto Show. Source: Bowling Green Daily News- 9 comments

-

- bowling green

- chevrolet corvette

-

(and 2 more)

Tagged with:

-

Volvo Announces South Carolina As Its Home For A New Factory

William Maley posted an article in Volvo

This morning, Volvo announced that it will be building its first pant in North America. Berkeley County, South Carolina has been chosen as the place where the Swedish automaker will invest up to $500 million for a new facility that is expected to go online in 2018. The new plant will employ up 2,000 people when the plant opens and 8,000 people in the longer term. Why did Volvo pick South Carolina? The automaker explained that the state offered an existing infrastructure and manufacturing base, along with an easy access to international ports. That last point is key as the plant will be building vehicles for both export and local consumption. “We’re excited to build our first American factory in South Carolina and we look forward to helping grow the local community and economy. We were impressed with the friendliness, work ethic and passion of the people in the Charleston area,” said Lex Kerssemakers, President and CEO of Volvo Cars of North America. Volvo hasn't said what vehicles will be built at the plant at this time. Source: Volvo Press Release is on Page 2 Volvo Cars selects South Carolina for its first American factory (ROCKLEIGH, NJ – May 11, 2015) Volvo Cars has chosen Berkeley County, South Carolina as the location of its first American factory, investing up to $500 Million in a facility with a capacity to initially produce up to 100,000 cars per year. The Berkeley County factory, located outside of Charleston, will make latest generation Volvo models for sale in the United States and for export. Construction will begin in early autumn 2015, with the first vehicles expected to roll off the assembly line in 2018. Once completed, Volvo Cars will be able to manufacture vehicles on three continents, underscoring its position as a truly global car maker. It already operates two plants in Europe and two in China. The new US plant forms part of an ambitious medium term expansion plan to double global sales, boost market share and lift profitability. “This new global industrial footprint and a complete product renewal forms the foundation for our growth and profitability targets,” said Håkan Samuelsson, president and chief executive of Volvo Car Corporation. Volvo began importing cars to the US in 1955. With the development of an American factory, the company crosses an important threshold from an automotive importer to a domestic manufacturer. “We’re excited to build our first American factory in South Carolina and we look forward to helping grow the local community and economy.” said Lex Kerssemakers, President and CEO of Volvo Cars of North America, “We were impressed with the friendliness, work ethic and passion of the people in the Charleston area.” The decision to choose Berkeley County was taken as a result of its easy access to international ports and infrastructure, a well-trained labor force, attractive investment environment and experience in the high tech manufacturing sector. Volvo Cars estimates that the factory will employ up to 2,000 people over the next decade and up to 4,000 people in the longer term. An economic impact analysis compiled by Dr. Frank Hefner at the College of Charleston estimates that, for an initial 2,000 direct jobs, more than 8,000 total jobs would be created as a result. The plant would contribute approximately $4.8 billion in total economic output on an annual basis. “This is a landmark moment and truly a great day in South Carolina as we welcome Volvo Cars’ first American manufacturing plant to our state,” said Nikki Haley, Governor of South Carolina, “Volvo’s presence and commitment to the community will be felt for decades to come. We are proud to have this global leader in car manufacturing join and strengthen South Carolina’s automotive industry.” readySC™, a division of the S.C. Technical College System, is assisting with the recruitment and training for positions at the new plant. All information on hiring will be posted as available at the readySC portal, readysc.org/volvo/. Potential suppliers or vendors interested in doing business with the company should contact the South Carolina Department of Commerce’s Buy South Carolina program by emailing [email protected].- 3 comments

-

- Assembly Line

- Plant

-

(and 3 more)

Tagged with:

-

This morning, Volvo announced that it will be building its first pant in North America. Berkeley County, South Carolina has been chosen as the place where the Swedish automaker will invest up to $500 million for a new facility that is expected to go online in 2018. The new plant will employ up 2,000 people when the plant opens and 8,000 people in the longer term. Why did Volvo pick South Carolina? The automaker explained that the state offered an existing infrastructure and manufacturing base, along with an easy access to international ports. That last point is key as the plant will be building vehicles for both export and local consumption. “We’re excited to build our first American factory in South Carolina and we look forward to helping grow the local community and economy. We were impressed with the friendliness, work ethic and passion of the people in the Charleston area,” said Lex Kerssemakers, President and CEO of Volvo Cars of North America. Volvo hasn't said what vehicles will be built at the plant at this time. Source: Volvo Press Release is on Page 2 Volvo Cars selects South Carolina for its first American factory (ROCKLEIGH, NJ – May 11, 2015) Volvo Cars has chosen Berkeley County, South Carolina as the location of its first American factory, investing up to $500 Million in a facility with a capacity to initially produce up to 100,000 cars per year. The Berkeley County factory, located outside of Charleston, will make latest generation Volvo models for sale in the United States and for export. Construction will begin in early autumn 2015, with the first vehicles expected to roll off the assembly line in 2018. Once completed, Volvo Cars will be able to manufacture vehicles on three continents, underscoring its position as a truly global car maker. It already operates two plants in Europe and two in China. The new US plant forms part of an ambitious medium term expansion plan to double global sales, boost market share and lift profitability. “This new global industrial footprint and a complete product renewal forms the foundation for our growth and profitability targets,” said Håkan Samuelsson, president and chief executive of Volvo Car Corporation. Volvo began importing cars to the US in 1955. With the development of an American factory, the company crosses an important threshold from an automotive importer to a domestic manufacturer. “We’re excited to build our first American factory in South Carolina and we look forward to helping grow the local community and economy.” said Lex Kerssemakers, President and CEO of Volvo Cars of North America, “We were impressed with the friendliness, work ethic and passion of the people in the Charleston area.” The decision to choose Berkeley County was taken as a result of its easy access to international ports and infrastructure, a well-trained labor force, attractive investment environment and experience in the high tech manufacturing sector. Volvo Cars estimates that the factory will employ up to 2,000 people over the next decade and up to 4,000 people in the longer term. An economic impact analysis compiled by Dr. Frank Hefner at the College of Charleston estimates that, for an initial 2,000 direct jobs, more than 8,000 total jobs would be created as a result. The plant would contribute approximately $4.8 billion in total economic output on an annual basis. “This is a landmark moment and truly a great day in South Carolina as we welcome Volvo Cars’ first American manufacturing plant to our state,” said Nikki Haley, Governor of South Carolina, “Volvo’s presence and commitment to the community will be felt for decades to come. We are proud to have this global leader in car manufacturing join and strengthen South Carolina’s automotive industry.” readySC™, a division of the S.C. Technical College System, is assisting with the recruitment and training for positions at the new plant. All information on hiring will be posted as available at the readySC portal, readysc.org/volvo/. Potential suppliers or vendors interested in doing business with the company should contact the South Carolina Department of Commerce’s Buy South Carolina program by emailing [email protected]. View full article

- 3 replies

-

- Assembly Line

- Plant

-

(and 3 more)

Tagged with:

-

Ford Cuts A Shift At Wayne Assembly Due To Slow Compact Sales

William Maley posted an article in Ford

Ford announced this week that it will be cutting a shift at its Michigan Assembly Plant in Wayne, MI - where the Focus and C-Max are built - due to slumping sales. Ford says the cut will affect a total of 700 workers - 673 hourly workers and 27 salaried employees. "Ford will be working to redeploy affected hourly employees and they will be considered first for southeast Michigan opportunities as they become available," Ford said in statement to The Detroit News. Salaried employees will be moved to other Ford facilities. Sales of the Ford Focus dropped 14.5 percent last month, despite a refreshed model and a price cut on the electric model. The C-Max was hit worse with a sales drop of 22.9 percent. Automotive News reports there had been rumors flying around for weeks about Ford cutting the third shift. When asked last week about this, Ford said they had now changes in store for the plant. Coincidentally, this announcement comes a few days after Ford announced a $2.5 billion investment in new transmission and engine plants in Mexico. Source: Automotive News (Subscription Required), The Detroit News -

Ford announced this week that it will be cutting a shift at its Michigan Assembly Plant in Wayne, MI - where the Focus and C-Max are built - due to slumping sales. Ford says the cut will affect a total of 700 workers - 673 hourly workers and 27 salaried employees. "Ford will be working to redeploy affected hourly employees and they will be considered first for southeast Michigan opportunities as they become available," Ford said in statement to The Detroit News. Salaried employees will be moved to other Ford facilities. Sales of the Ford Focus dropped 14.5 percent last month, despite a refreshed model and a price cut on the electric model. The C-Max was hit worse with a sales drop of 22.9 percent. Automotive News reports there had been rumors flying around for weeks about Ford cutting the third shift. When asked last week about this, Ford said they had now changes in store for the plant. Coincidentally, this announcement comes a few days after Ford announced a $2.5 billion investment in new transmission and engine plants in Mexico. Source: Automotive News (Subscription Required), The Detroit News View full article

-

It seems the Chevrolet Bolt concept we saw at Detroit last month is possibly going into production. Reuters has learned from sources that production for the Bolt and sister Opel model will kick off in October 2016 at General Motors' Lake Orion assembly plant. The plant is currently home Chevrolet Sonic and Buick Verano. Sources say the company is planning to build around 25,000 to 30,000 units per year. As for Bolt itself, it will use GM's Gamma small car platform and will share the same basic set of components as the next-generation Sonic due out in late 2016. Sales will begin in early 2017. A GM spokesman declined to comment on the report. Source: Reuters

- 21 comments

-

It seems the Chevrolet Bolt concept we saw at Detroit last month is possibly going into production. Reuters has learned from sources that production for the Bolt and sister Opel model will kick off in October 2016 at General Motors' Lake Orion assembly plant. The plant is currently home Chevrolet Sonic and Buick Verano. Sources say the company is planning to build around 25,000 to 30,000 units per year. As for Bolt itself, it will use GM's Gamma small car platform and will share the same basic set of components as the next-generation Sonic due out in late 2016. Sales will begin in early 2017. A GM spokesman declined to comment on the report. Source: Reuters View full article

- 21 replies

-

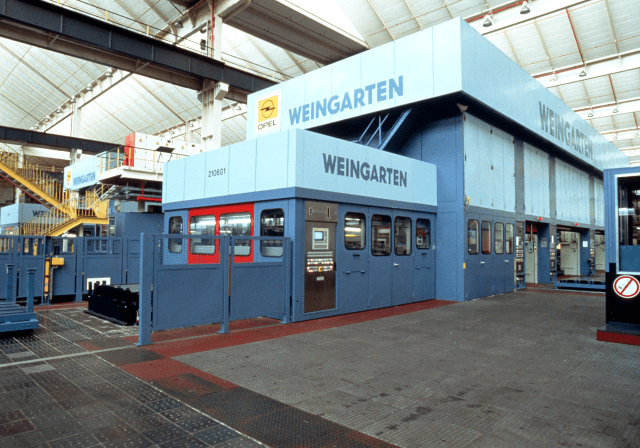

William Maley Staff Writer - CheersandGears.com December 10, 2012 Opel announced today that it will close the Bochum plant in Germany in 2016 when production of the current Opel Zafira ends. "Despite rigorous efforts, there was no success in changing the situation. The main reasons are the dramatic declines in the European car market and the enormous overcapacity in the entire European auto industry," Opel said in a statement today. The closure is part of a long-term recovery plan called Drive Opel 2022. Under the plan, Opel will work on trying to be more cost efficient, improving the brand's image, strengthen market share, and entering new markets and segments. The plan also says by 2016, Opel will have 23 new models and 13 new engines. The closure of Bochum also means the loss of 3,300 jobs. Opel says they will preserve some jobs in its Bochum warehouse and is looking at allocating new component production to the region. Local labour leader Rainer Einenkel says the union is hopeful about trying to save Bochum. Meanwhile, the German government expects GM to provide severance packages for the workers. "It's a severe blow that affects a lot of people and their families and the Bochum region as well. The German government has the expectation that the parent company General Motors will do everything possible to find socially acceptable solutions," said Georg Streiter, spokesman for German Chancellor Angela Merkel. Source: Opel, Automotive News Europe (Subscription Required) William Maley is a staff writer for Cheers & Gears. He can be reached at [email protected] you can follow him on twitter at @realmudmonster. Press Release is on Page 2 Opel plans to end car production in Bochum in 2016 2012-12-10 Warehouse to remain in Bochum and probably to be expanded New component production could be allocated in Bochum Initiative "Bochum Perspective 2022“ to secure existing and create new jobs Goal: No forced redundancies before run-out of current Zafira Attractive separation packages Germany stays backbone and home of Opel Announcement is part of long-term plan “Drive! 2022” Ruesselsheim. Adam Opel AG management today informed its employees that vehicle production is planned to end in Bochum at the end of the current Zafira lifecycle – expected in 2016. In June, Opel announced that no successor to the current Zafira is planned to be allocated in Bochum in view of the shrinking European car market and the overcapacities in the automotive industry. Despite intensive efforts this situation could not be changed. The warehouse in Bochum will continue to offer jobs beyond 2016 and could be expanded. Additionally, Opel is negotiating with the employee representatives to allocate a new component production in Bochum. On top of this, the working group “Bochum Perspective 2022”, which was recently established by Opel, has the objective to focus on site development, to secure existing jobs and create new ones in the City of Bochum and the entire Ruhr region. “Bochum Perspective 2022” is composed of representatives of local and regional government, along with leaders and innovators from labor, industry, academia and financial institutions located in North Rhine-Westphalia. Opel will support the initiative financially and personnel-wise. “Building on the Bochum Perspective 2022, we have a clear goal for securing a significant number of tariff-bound jobs at Adam Opel AG. They include positions in our warehouses and potentially component production. Opel takes its responsibility seriously and will implement still-necessary job reductions in the most socially responsible way. The goal of our negotiations with the works council is to refrain from forced redundancies before the run-out of the current Zafira,” said Steve Girsky, GM Vice Chairman, Chairman of the Opel Supervisory Board and Acting President of GM Europe. "Germany is our most important market and with about 20,000 employees the backbone and home of our brand. And this will stay this way in the future,” Opel Deputy CEO Dr. Thomas Sedran said. Opel also has the responsibility for its independent dealers; in North-Rhine-Westphalia alone there are 320 Opel dealers who employ about 5,300 employees. This move is part of the company’s long term plan “Drive Opel 2022” which targets break-even results by mid-decade. Opel plans to increase its revenue and variable profit significantly by more cost-efficiency, re-focusing its go-to-market strategy, improving the image of the Opel brand, strengthening the quality of market share and entering new markets and segments. From 2012 to 2016, Opel will launch 23 new models and 13 new engines in total. View full article

-

William Maley Staff Writer - CheersandGears.com December 10, 2012 Opel announced today that it will close the Bochum plant in Germany in 2016 when production of the current Opel Zafira ends. "Despite rigorous efforts, there was no success in changing the situation. The main reasons are the dramatic declines in the European car market and the enormous overcapacity in the entire European auto industry," Opel said in a statement today. The closure is part of a long-term recovery plan called Drive Opel 2022. Under the plan, Opel will work on trying to be more cost efficient, improving the brand's image, strengthen market share, and entering new markets and segments. The plan also says by 2016, Opel will have 23 new models and 13 new engines. The closure of Bochum also means the loss of 3,300 jobs. Opel says they will preserve some jobs in its Bochum warehouse and is looking at allocating new component production to the region. Local labour leader Rainer Einenkel says the union is hopeful about trying to save Bochum. Meanwhile, the German government expects GM to provide severance packages for the workers. "It's a severe blow that affects a lot of people and their families and the Bochum region as well. The German government has the expectation that the parent company General Motors will do everything possible to find socially acceptable solutions," said Georg Streiter, spokesman for German Chancellor Angela Merkel. Source: Opel, Automotive News Europe (Subscription Required) William Maley is a staff writer for Cheers & Gears. He can be reached at [email protected] you can follow him on twitter at @realmudmonster. Press Release is on Page 2 Opel plans to end car production in Bochum in 2016 2012-12-10 Warehouse to remain in Bochum and probably to be expanded New component production could be allocated in Bochum Initiative "Bochum Perspective 2022“ to secure existing and create new jobs Goal: No forced redundancies before run-out of current Zafira Attractive separation packages Germany stays backbone and home of Opel Announcement is part of long-term plan “Drive! 2022” Ruesselsheim. Adam Opel AG management today informed its employees that vehicle production is planned to end in Bochum at the end of the current Zafira lifecycle – expected in 2016. In June, Opel announced that no successor to the current Zafira is planned to be allocated in Bochum in view of the shrinking European car market and the overcapacities in the automotive industry. Despite intensive efforts this situation could not be changed. The warehouse in Bochum will continue to offer jobs beyond 2016 and could be expanded. Additionally, Opel is negotiating with the employee representatives to allocate a new component production in Bochum. On top of this, the working group “Bochum Perspective 2022”, which was recently established by Opel, has the objective to focus on site development, to secure existing jobs and create new ones in the City of Bochum and the entire Ruhr region. “Bochum Perspective 2022” is composed of representatives of local and regional government, along with leaders and innovators from labor, industry, academia and financial institutions located in North Rhine-Westphalia. Opel will support the initiative financially and personnel-wise. “Building on the Bochum Perspective 2022, we have a clear goal for securing a significant number of tariff-bound jobs at Adam Opel AG. They include positions in our warehouses and potentially component production. Opel takes its responsibility seriously and will implement still-necessary job reductions in the most socially responsible way. The goal of our negotiations with the works council is to refrain from forced redundancies before the run-out of the current Zafira,” said Steve Girsky, GM Vice Chairman, Chairman of the Opel Supervisory Board and Acting President of GM Europe. "Germany is our most important market and with about 20,000 employees the backbone and home of our brand. And this will stay this way in the future,” Opel Deputy CEO Dr. Thomas Sedran said. Opel also has the responsibility for its independent dealers; in North-Rhine-Westphalia alone there are 320 Opel dealers who employ about 5,300 employees. This move is part of the company’s long term plan “Drive Opel 2022” which targets break-even results by mid-decade. Opel plans to increase its revenue and variable profit significantly by more cost-efficiency, re-focusing its go-to-market strategy, improving the image of the Opel brand, strengthening the quality of market share and entering new markets and segments. From 2012 to 2016, Opel will launch 23 new models and 13 new engines in total.

-

William Maley Staff Writer - CheersandGears.com June 25, 2012 Volvo looks to joining its compatriots in Germany, South Korea, and Japan with building vehicles in North America. In a interview with Bloomberg, Volvo CEO Stefan Jacoby said they're looking for a partner to manufacture cars in North America. "In the medium term, five to six years, we need to find a proper solution in North America. Building a plant ourselves is maybe more unlikely. I’m looking for a partner that could help us utilize a North American plant," As to who, Jacoby said they are open to all manufacturers, even Fiat. "Fiat is obviously one of the alternatives. If you speak to Marchionne, just tell him to call me" Jacoby said. Source: Bloomberg William Maley is a staff writer for Cheers & Gears. He can be reached at [email protected] or you can follow him on twitter at @realmudmonster. View full article

- 7 replies

-

- North America

- Partner

-

(and 2 more)

Tagged with:

-

William Maley Staff Writer - CheersandGears.com June 25, 2012 Volvo looks to joining its compatriots in Germany, South Korea, and Japan with building vehicles in North America. In a interview with Bloomberg, Volvo CEO Stefan Jacoby said they're looking for a partner to manufacture cars in North America. "In the medium term, five to six years, we need to find a proper solution in North America. Building a plant ourselves is maybe more unlikely. I’m looking for a partner that could help us utilize a North American plant," As to who, Jacoby said they are open to all manufacturers, even Fiat. "Fiat is obviously one of the alternatives. If you speak to Marchionne, just tell him to call me" Jacoby said. Source: Bloomberg William Maley is a staff writer for Cheers & Gears. He can be reached at [email protected] or you can follow him on twitter at @realmudmonster.

- 7 comments

-

- North America

- Partner

-

(and 2 more)

Tagged with: